Features

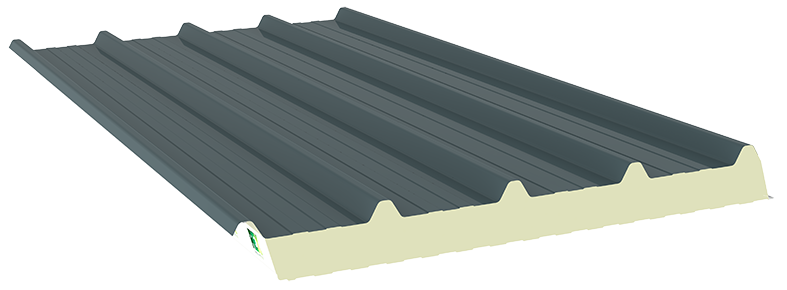

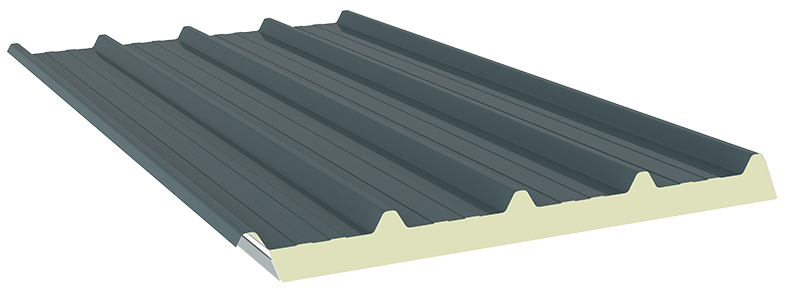

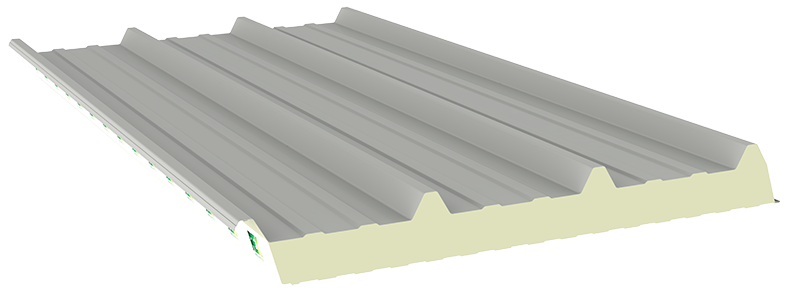

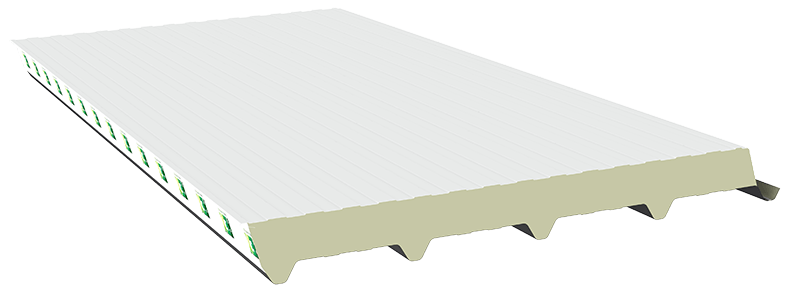

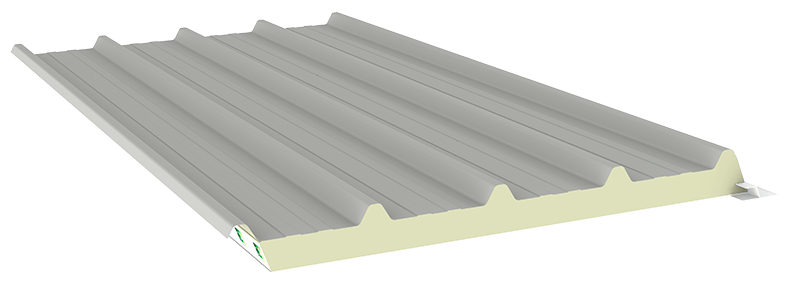

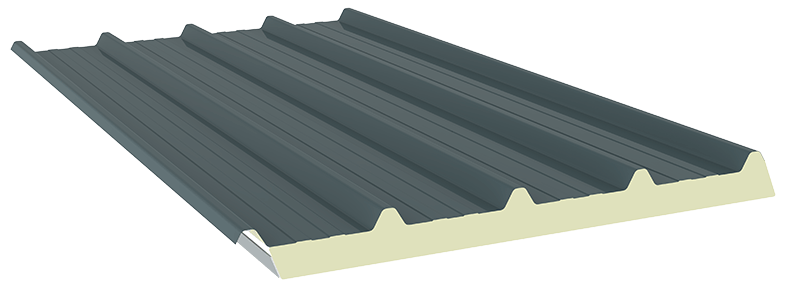

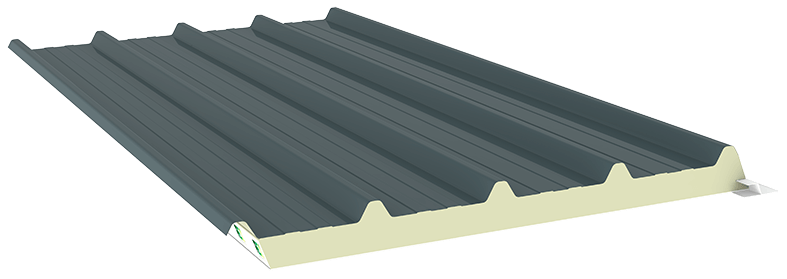

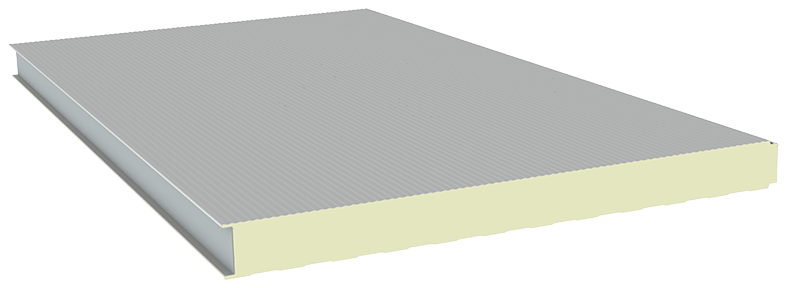

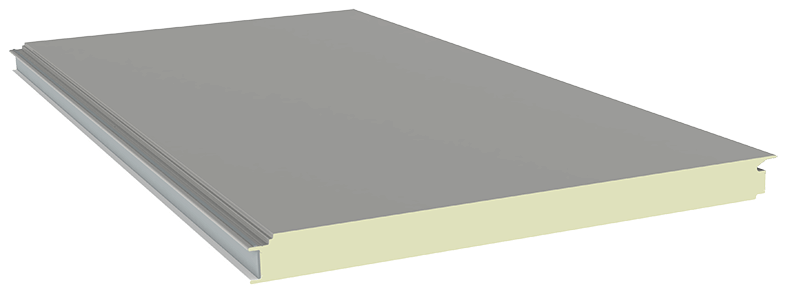

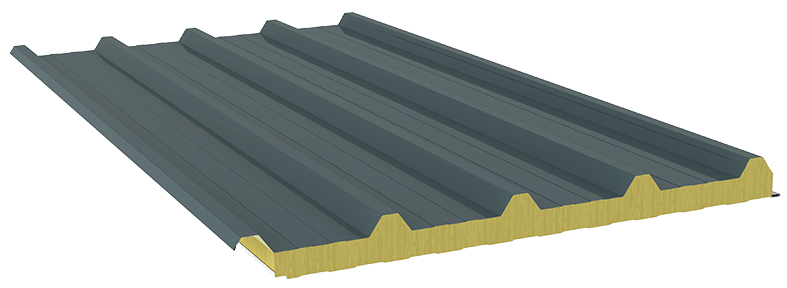

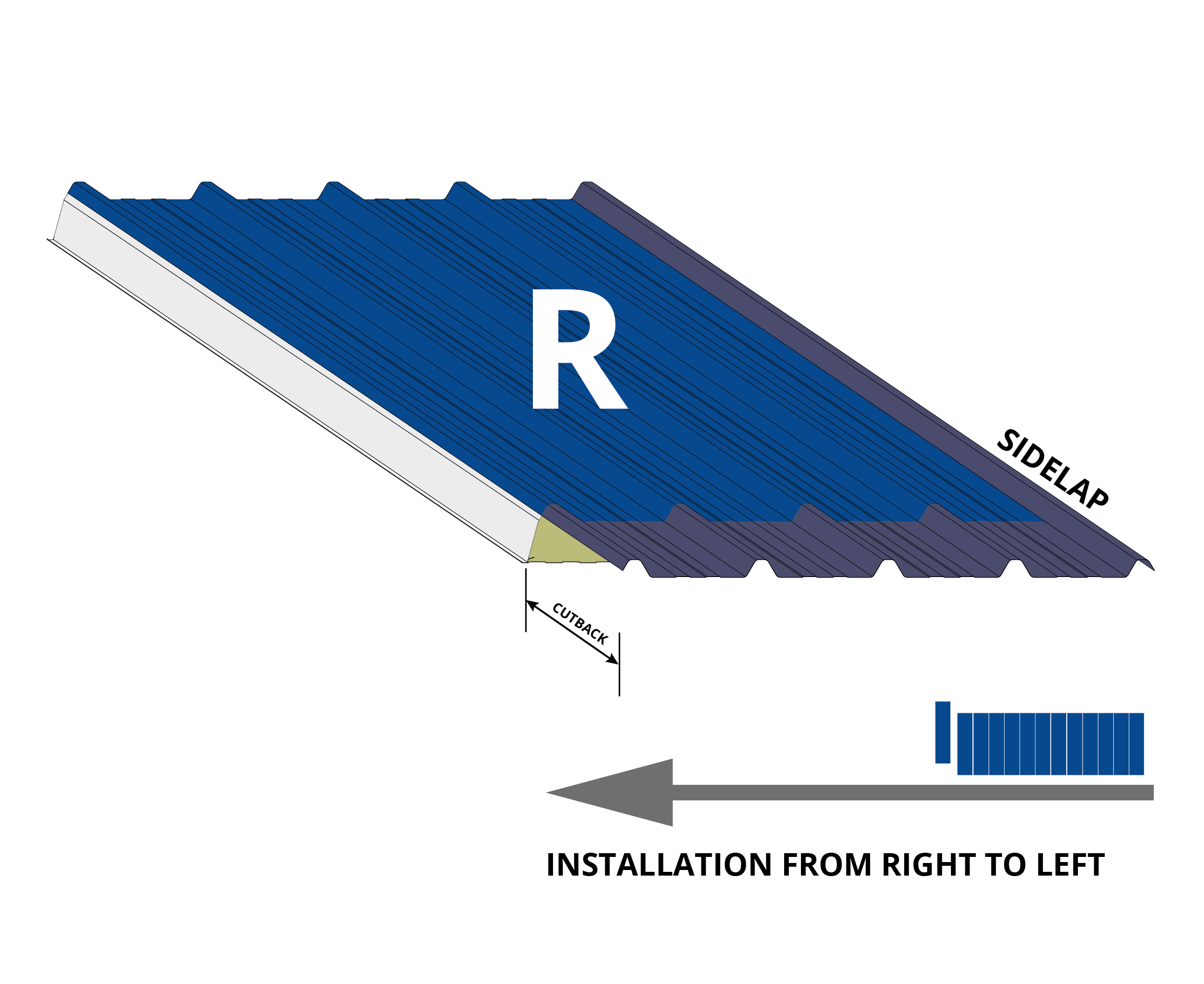

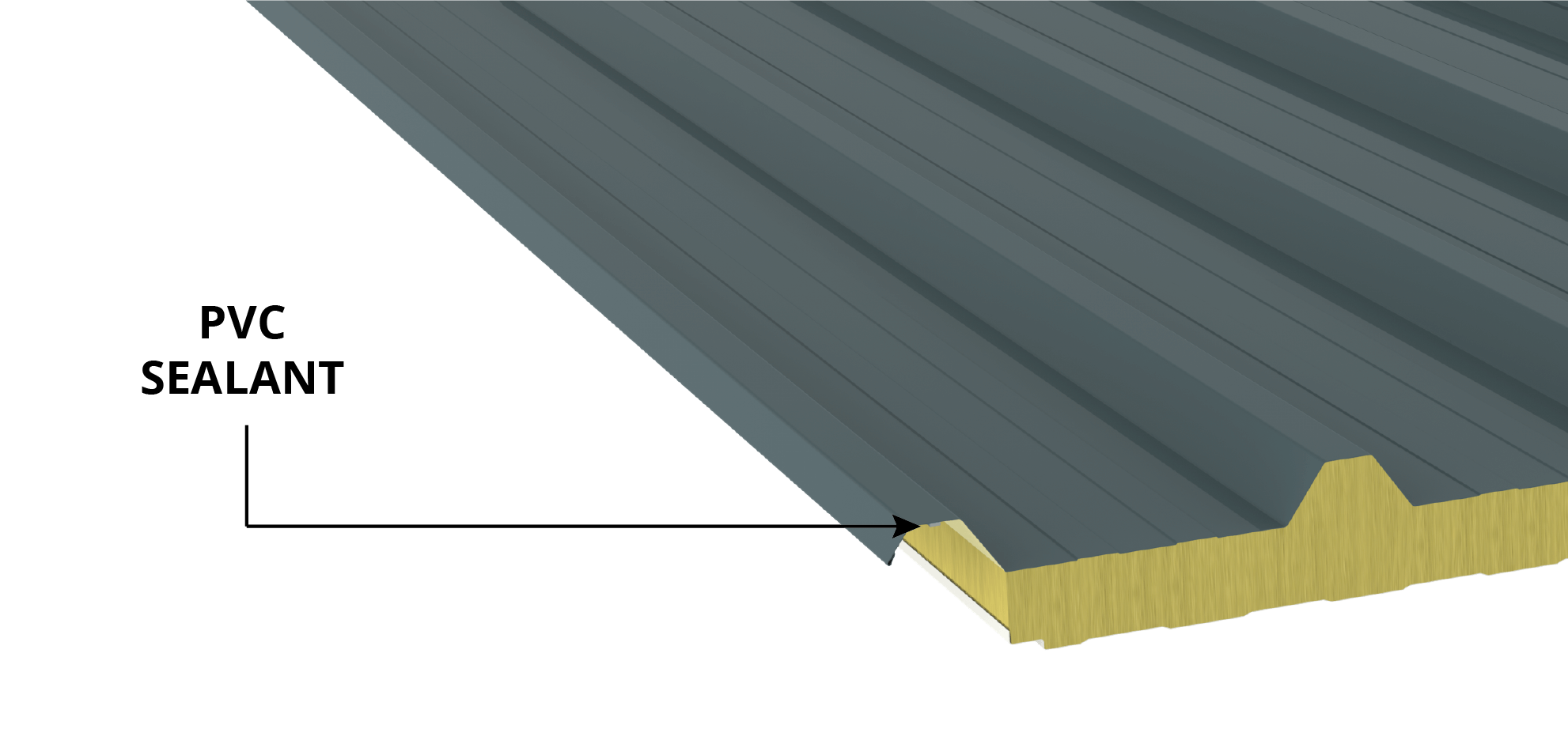

- • Trapezoidal external sheet “ROOF 4”

- • Mineral Wool core material

- • For pitched roofs starting from 4°

- • Standard fire class A2-S1-D0

- • Up to 120 minutes fire insulation and integrity (EI120)

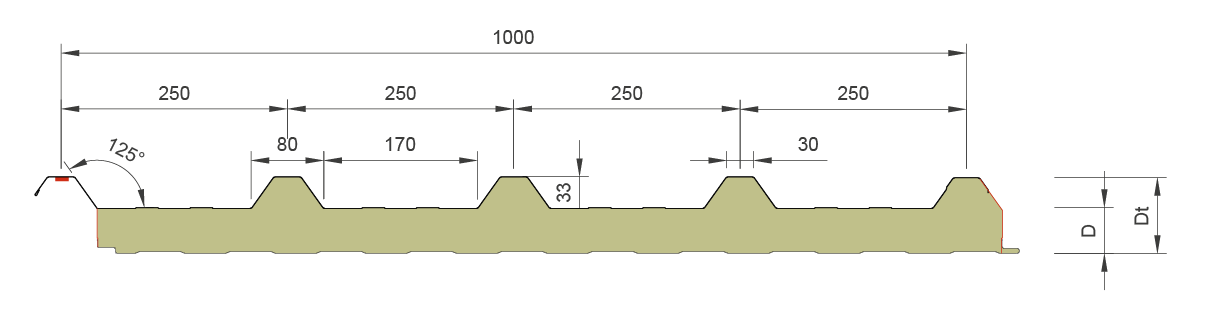

- • Cover width 1000 mm

- • Thicknesses from 50 mm to 200 mm

- • Insulation value down to U = 0,20 W/m2 .k